2021-10-11

2021-10-11

Is your supply chain covered?

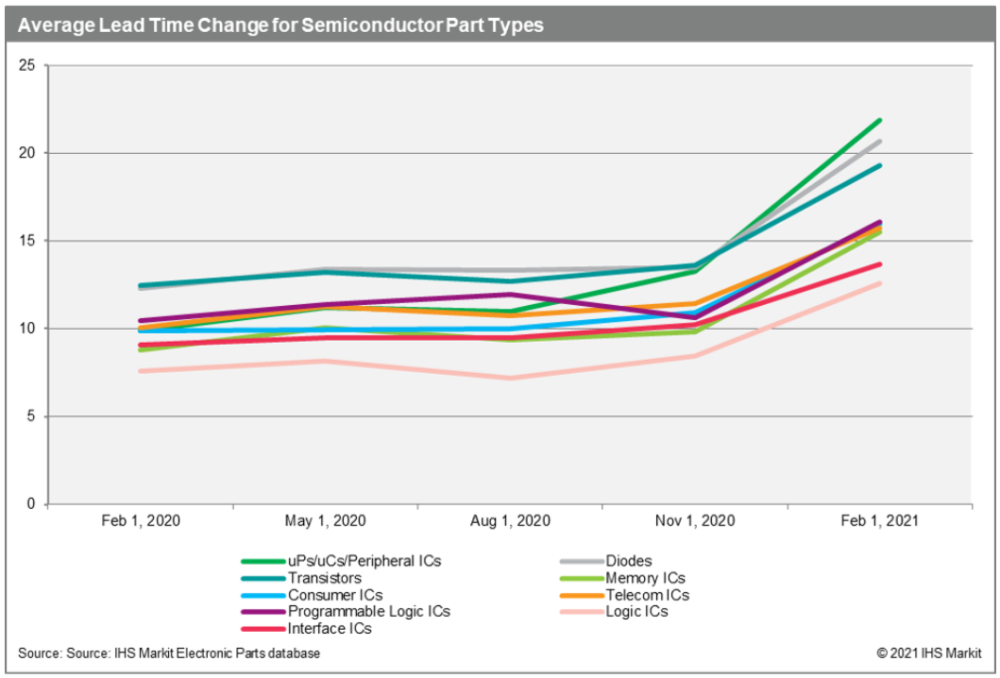

The electronics components supply market continues to face significant challenges; prices are going up and lead times are still increasing for all product technologies and late/failed deliveries are now commonplace. In addition, several manufacturers have experienced raw material cost increases which are being passed on and we expect this trend to continue.

The combination of the pandemic and strong economic factors in the market is driving demand to significantly exceed supply. Wafer fabs including test and assembly are now at or beyond full capacity. On average, demand versus supply is in the range of 120%. For some materials, capacity is now critical, leading to unprecedented manufacturing lead time increases. Is your supply chain covered?

The latest market updates predict that electronic materials will remain in crisis for at least 18 months as capacity is put in place to meet demand.

To compound these challenges, we have had storms, earthquakes, manufacturing factory fires and freight reductions to contend with.

Managing the Supply Chain

A good CEM needs to navigate the pressures of the supply chain whilst also finding ways of adding value to the outsourcing relationship and simplifying life for its customers.

Through our key supplier relationships and NOTE’s Central Sourcing division, we receive regular manufacturer updates from our strategic distribution partners and forecast the forward trends to allow us to work with our suppliers to minimise disruptions as much as possible.

Order visibility is critical to ensure continuity of supply. For years we have worked on supply chain solutions that rely on “normal” lead times being less than eight weeks, back up with buffer arrangements for lead times greater than eight weeks. NOTE Windsor’s Kanban system, forecast and schedules have helped us build strong and reliable supply chains. However, that is no longer sufficient for the lead time challenges we are now facing.

Nurturing long term partnerships

At NOTE, we nurture long term partnerships with our suppliers, meeting regularly to review demand and forecast and look at lead time updates to try and ensure continuity of supply of components, and they in turn support us with our requirements.

Importance of placing orders and timely decisions

We work with our customers and OEMs to review their requirements to accommodate these increasing lead times, encouraging them to place orders early, enabling us to secure components for the build.

We also get involved at the design stages for a project, so that we can look at purchasing long lead time items in preparation for the final release of the product.

If you can provide us with long term visibility, the more we can plan and forecast, updating you with changing market conditions including price increases and lead times.

In any economic climate, an effective supply chain cannot be taken for granted, like any other part of the business, it must be subject to continuous improvement. Our goal is to be the best collaborative partner, adding value by bringing leading quality and high delivery precision for a competitive cost.